In the present article, we are treating the main typologies of available stepper motors on the market, the essential structural aspects and their operation characteristics in static and dynamic conditions.

The stepper motor is used in small-power drives because it is less efficient than other motors. It allows achieving high positioning precisions and it is suitable for the sectors of robotics, automotive, 2D plotters, 3D printers and several other ambits.

Their name derives from the fact that a well precise angular rotation, precisely called step, is set at each control.

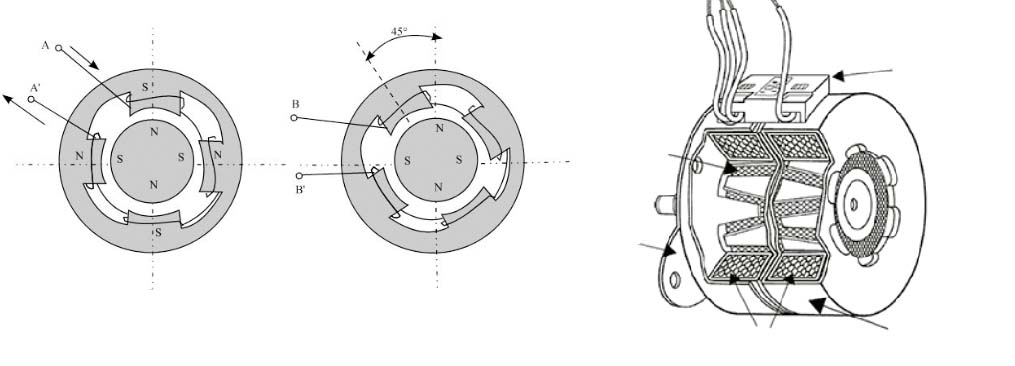

In the ambit of the manufacturing industry, stepper motors are classified as follows:

Permanent magnets (PM);

Variable reluctance (VR);

Hybrid (HY).

Torque developed in static conditions

Under static conditions, a stepper motor of whatever kind can develop the following torque:

Holding Torque. Let us consider a stepper motor of any type (PM, VR or HY) and let us power a single phase. The rotor will position itself in a determinate stable position.

Torque developed in dynamic conditions

Operating the motor with some piloting circuits, it is possible to assess the operation of stepper motors in dynamic conditions. In technical literature, we can distinguish two operation typologies (23hs41-1804s,23hs45-3504s).

Operation in pull-out (pull-out torque). The maximum torque the motor can develop during the rotation is called pull-out torque and it is equal to about 90% of the holding torque. In practice, we suggest choosing the size of the motor to work with torque corresponding to about 50% of the Holding Torque. At the so-called pull-out speed, the relative torque annuls. Catalogues, then, provide graphs of the Pull-out torque according to speed.

Operation in pull-in (pull-in torque). To allow the motor to develop the Pull-out torque, it is necessary that the drive takes it to the wished speed, through opportune acceleration ramps.

Conclusions

Stepper motors play an important role in the manufacturing industry world. Their use prevailingly depends on expectations and applications. If we aim at high precisions, mechanical and electric sturdiness, user friendliness, control and maintenance of the rotor’s position also without power supply, then this motor typology is ideal. However, we should take some limits into account, like the impossibility of having high speeds, the heat production and, especially, the need of providing for suitable piloting systems.

https://teleadreson.com/betty-alan,guagnzhou-1GGKANRhigA.html

http://dailybamablog.com/which-is-right-for-your-application-between-stepper-motor-and-servo-motor/